Following the Non-Disclosure Agreement, we will refer to the apparel retailer as “Korean Clothing,” which operates a network of stores across various cities in the Philippines. Catering to a diverse range of fashion preferences, the company offers an extensive array of clothing items, encompassing both casual wear and formal attire.

Clothes Shipping challenge

- Geographical Spread: Operating stores across multiple cities in the Philippines posed logistical challenges in terms of coordinating shipments efficiently.

- Inventory Management: Maintaining optimal inventory levels at each store while minimizing excess stock or stockouts required careful planning.

- Shipping Costs: High shipping costs due to multiple shipments from various suppliers and between stores impacted profit margins.

- Delivery Timeliness: Ensuring timely delivery to each store to meet customer demands and seasonal fluctuations in sales was crucial.

- Supply Chain Visibility: Limited visibility into the supply chain made it challenging to track shipments and anticipate delays.

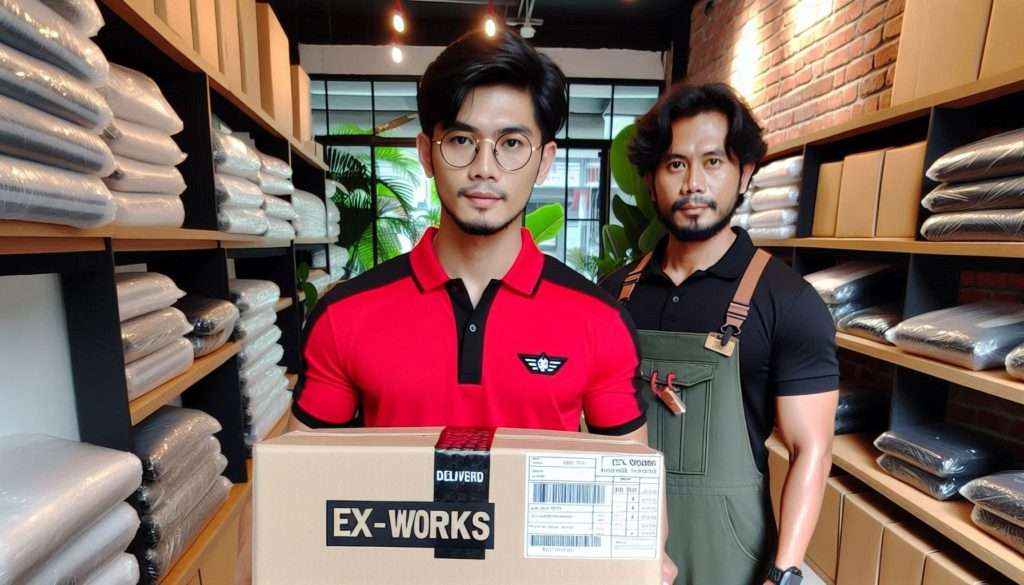

Subscribe to the Ex-works24/7 newsletter

Clothes Shipping strategy

To address these challenges, Trendy Threads Inc. implemented the following strategies:

- Centralized Distribution Center: Establishing a centralized distribution center (DC) allowed the company to consolidate inventory and manage shipments more efficiently. Located strategically, the DC served as a hub for receiving merchandise from suppliers and distributing it to stores.

- Inventory Optimization Software: Investing in inventory optimization software enabled the company to forecast demand accurately and allocate inventory based on store requirements. This helped in reducing stockouts and excess inventory.

- Consolidated Shipments: Implementing a consolidated shipping approach, where multiple orders were bundled into a single shipment, significantly reduced shipping costs. By leveraging economies of scale, the company negotiated favorable freight rates with carriers.

- Route Optimization: Utilizing route optimization software optimized delivery routes, minimizing transit times and fuel costs. Real-time tracking of shipments enhanced visibility and allowed proactive management of delivery schedules.

- Vendor Collaboration: Collaborating closely with suppliers improved supply chain visibility and enabled better coordination of incoming shipments. Implementing vendor-managed inventory (VMI) systems streamlined the replenishment process.

Clothe Shipping result

- Cost Savings: Through the consolidation of shipments and route optimization, the company realized significant reductions in shipping expenses, resulting in substantial cost savings.

- Enhanced Efficiency: Streamlining processes and establishing centralized distribution enhanced operational efficiency, thereby reducing lead times and elevating customer satisfaction levels.

- Inventory Optimization: Improved inventory management practices led to decreased instances of stockouts and minimized excess inventory, thereby optimizing working capital utilization.

- Improved Visibility: The implementation of real-time shipment tracking and enhanced collaboration with suppliers bolstered supply chain visibility, facilitating proactive decision-making.

- Scalability: The implemented solutions provided a scalable framework, enabling Korean Clothing to effectively navigate evolving market dynamics and seamlessly expand its operations.

Conclusion: Through the utilization of pioneering logistics solutions and the integration of technology, Korean Clothing revolutionized its clothes shipping operations, facilitating effective multi-store distribution across the Philippines. The deliberate emphasis on cost optimization, inventory management, and supply chain visibility not only bolstered profitability but also positioned the company for enduring growth within the fiercely competitive retail sector.