Shipping dangerous goods is a complex process that requires meticulous attention to detail and adherence to international regulations. This blog post will delve into the intricacies of shipping dangerous goods, the challenges involved, and the best practices to ensure safety and compliance.

Understanding Dangerous Goods

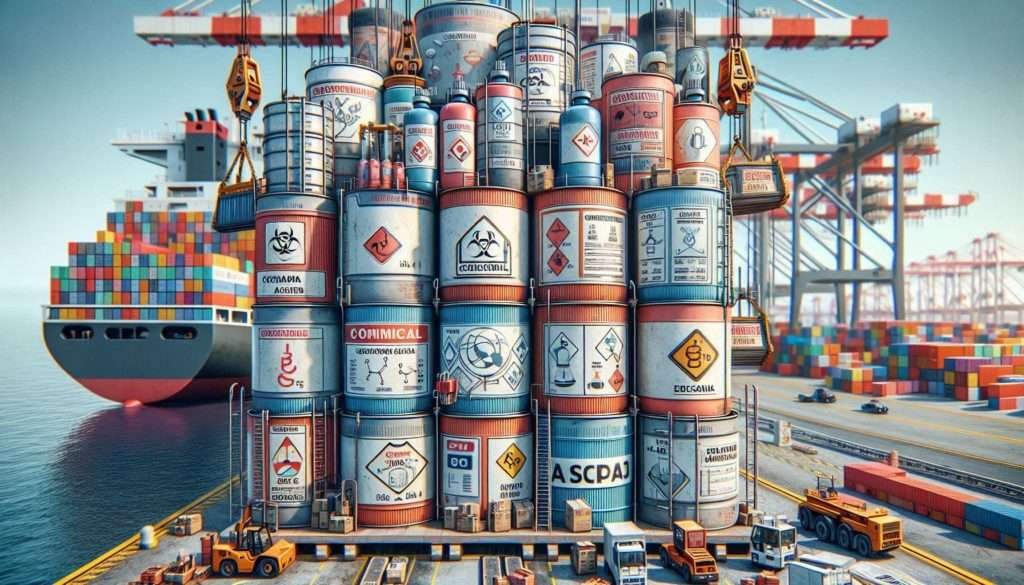

Dangerous goods, also known as hazardous materials, are items or substances that pose a risk to health, safety, property, or the environment. They can be anything from chemicals and radioactive materials to batteries and aerosols. Shipping these goods requires special handling to prevent accidents and ensure the safety of all involved.

Subscribe to the Ex-works24/7 newsletter

Background: Ex-Works Cargo operates globally, serving various industries such as pharmaceuticals, chemicals, and manufacturing. With a commitment to safety and compliance, they have established themselves as experts in handling DG cargoes.

Challenges Faced:

Diverse DG Classes: Handling DG cargoes involves dealing with different classes, each with its own set of regulations and safety requirements.

Storage Concerns: Ensuring proper storage at the origin to prevent accidents or chemical reactions during transit.

Loading Considerations: Segregating DG cargoes according to their classes and loading them safely into shipping containers to minimize risks.

Customs Compliance: Providing accurate documentation, including detailed MSDS, to facilitate smooth customs clearance.

Process Overview:

Preparation and Planning: Ex-Works Cargo’s team conducts a thorough assessment of the DG cargoes, identifying their classes and associated risks.

They collaborate with clients to gather comprehensive information about the DG cargoes, including MSDS and handling instructions.

Storage at Origin: Ex-Works Cargo ensures that DG cargoes are stored in designated areas at the origin, following strict safety protocols and segregation requirements based on class and compatibility.

Ex-works Cargo implements measures to prevent leaks, spills, or contamination during storage, such as using appropriate containment systems and labeling.

Loading Process:

- The loading process is meticulously planned, considering the compatibility of different DG classes and adhering to international regulations such as those outlined by the International Maritime Dangerous Goods (IMDG) Code.

- Ex-Works Cargo’s team segregates DG cargo into compatible groups and loads them into shipping containers using specialized equipment and handling procedures.

Documentation and Compliance:

- Ex-Works Cargo prepares detailed documentation for each shipment, including shipping manifests, transport documents, and MSDS.

- They ensure that MSDS provides comprehensive information about the properties, hazards, handling, and emergency procedures for each DG cargo.

- Compliance with international regulations, such as those set forth by the International Maritime Organization (IMO) and local customs authorities, is paramount throughout the process.

Result: Through strict adherence to safety protocols, segregation requirements, and regulatory guidelines, Ex-Works Cargo effectively manages diverse classes of DG cargoes, ensuring their secure transit from point of origin to final destination. Their dedication to compliance and proficiency in hazardous material handling has garnered the trust of clients spanning various sectors.

In summary, Ex-Works Cargo’s experience underscores the significance of meticulous planning, adherence to safety protocols, and regulatory conformity when dealing with DG cargoes. By employing robust processes from initial storage to customs clearance, they mitigate risks and guarantee the secure and efficient transport of hazardous materials, thereby bolstering the safety and reliability of global supply chains.